Slash Industrial Energy Costs & Meet Sustainability Goals

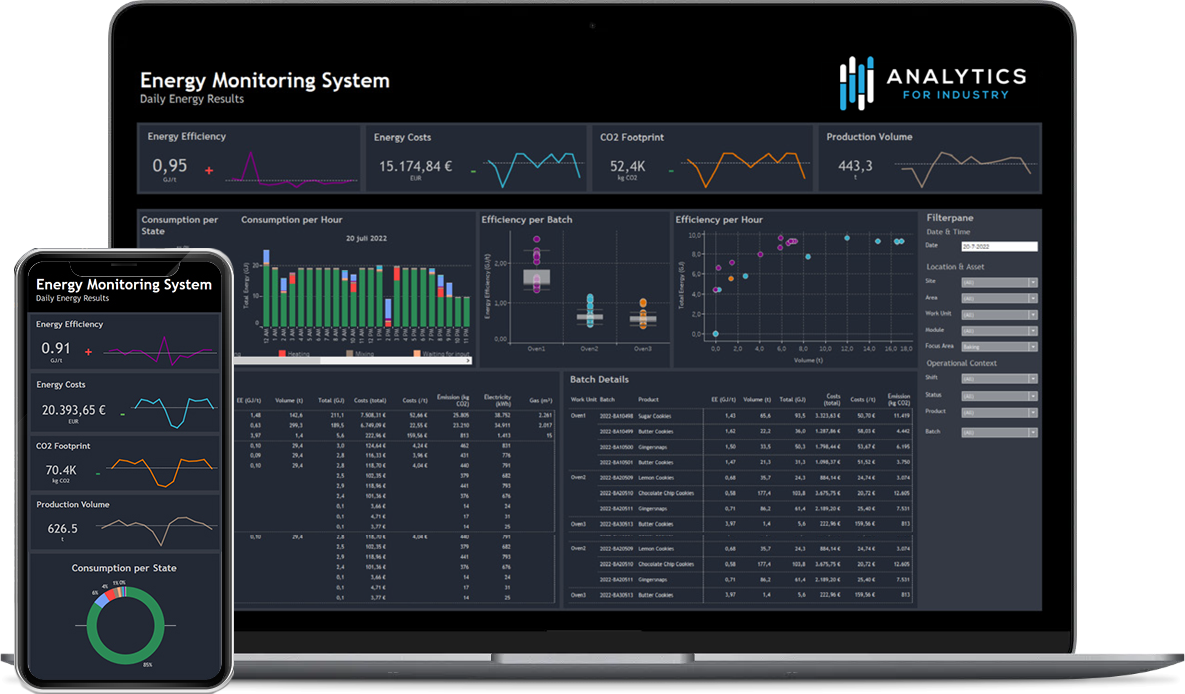

Uncover actionable insights from your data with our next-generation Energy Monitoring System (EMS)

The software is ideal for Food & Beverage and Pharmaceutical industries. Reduce your industrial energy consumption with our supercharged data insights. Bundle, transform, and visualize energy and process data to empower 360-informed decisions. Step out of the box and base your sustainability initiatives on evidence!

Why You Need an EMS

Traditional Energy Monitoring Systems (EMS) are like looking through a single lens. They offer limited data and lack context, making it hard to understand the "why" behind your energy consumption.

Our next-generation EMS goes beyond basic monitoring. We connect your energy data to all your production events, giving you a 360-degree view. This contextualization allows you to Identify hidden energy waste, Make data-driven decisions, and Empower all levels of your team.

Insight into energy consumption in the 1st year has resulted

in these reductions per production volume

EMS for Manufacturing

Advanced Energy Monitoring

See for yourself

Energy Consumption per hour

See your energy consumption per hour together with the state of your equipment at that specific moment.

Energy efficiency per batch

See your energy efficiency per batch compared to your specific equipment, and drill into your efficiency per hour.

Compare

Focus on your Energy consumption per day while comparing your Work Unit Efficiency and how they use Water, Electricity or Gas.

Energy efficiency per product

Compare different equipment making the same products, getting a clear view of where energy is used for the same product. Visualize energy setpoints and averages to compare equipments.

Ready to See Our EMS in Action?

Boost Profitability

Remove Variations

Prioritize investments

Data-Driven Efficiencies

We're a team of dedicated data specialists, committed to empowering companies with ambitious sustainability goals. Our expertise lies in harnessing solid data to drive real and impactful change.

Yearly Subscription

Unlock a transformative journey towards energy efficiency, delivering an impact that continues to benefit your company year after year.

Quick Results Guaranteed

Get up and running in just 5 days with our software. We don't believe in waiting for insights; we deliver them today, not tomorrow. Subscribe, plug in your data, and witness immediate impact.

What is an Energy Monitoring Solution (EMS)?

An Energy Monitoring Solution (EMS) is a software system that collects and analyzes data on energy consumption and other process variables in industrial facilities. The system can help businesses identify areas where energy is being wasted, track energy usage over time, and make data-driven decisions to improve energy efficiency and reduce costs. The most advanced EMS solutions can also build contextual relationships between energy- and process data, aligning sustainability and business objectives.

Why is sustainability important for businesses?

Sustainability is important for businesses for several reasons. First, it can help companies reduce their environmental impact by reducing energy, gas, and water usage across the whole production process. Second, consumers and investors are becoming more conscious of the environment and looking for sustainable practices in companies and products they support. This can lead to a positive impact on the brand image and sales. Finally, sustainability can also help businesses reduce costs by improving energy efficiency and reducing waste. By implementing sustainable practices, businesses can improve their bottom line while also contributing to a more sustainable future.

How can an EMS help businesses make better decisions?

An Energy Monitoring Solution (EMS) can help businesses make better decisions by providing real-time data on energy consumption and other process variables. This data can be used to identify areas where energy is being wasted, track energy usage over time, and make data-driven decisions to improve energy efficiency and reduce costs. The most advanced EMS solutions can also build contextual relationships between energy- and process data, aligning sustainability and business objectives. By providing insights into the complex manufacturing environment, an EMS can help businesses prioritize process and equipment investments, identify opportunities for cost savings, and ultimately become leaders in sustainability.

What are some key features to look for when selecting an EMS?

When selecting an Energy Monitoring Solution (EMS), there are several key features to look for. First, it's important to choose a solution that can integrate with existing systems and equipment, such as SCADA or Building Management Systems. This will ensure that the EMS can collect data from all relevant sources and provide a comprehensive view of energy usage. Second, look for a solution that provides real-time data visualization and analytics, allowing users to quickly identify areas for improvement and track progress over time. Third, consider the level of customization and flexibility offered by the EMS, as this can impact the ability to tailor the solution to specific business needs. Fourth, look for a solution that provides actionable insights and recommendations, rather than just raw data. Finally, consider the level of support and expertise offered by the EMS provider, including training, technical support, and ongoing maintenance. By selecting an EMS with these key features, businesses can ensure they are getting the most value from their investment and driving real results in sustainability

What options are there to provide data to the system?

The answer to this question depends on the source systems that are being used. EMS includes connectivity to a wide variety of standard drivers (300+) like BACnet, MQTT, Modbus, OPC, RS232/485 Siemens and many more. In case AVEVA / PI products are used, built-in publishers can be used to publish directly from the automation system. Data publishing can be set up within minutes. A full overview of connectivity options can be found in <Data Prerequisites – EMS>.We need to transform data to meet data prerequisites. What options are there to do this? In case data should be transformed before it is provided to the system (to meet data prerequisites), it is advised to solve this using edge software like AVEVA Edge or Crosser, or use custom scripting languages like Python or Microsoft Power Automate. Who is responsible for supplying data to the system in the project? This is usually a different project that’s handled by either the customer himself or a systems integrator. The complexity and duration of this action strongly depends on the data sources that are used to supply data to the system. Analytics for Industry supports customers in the preparatory stage of the project with advise on the best way to publish its data to the cloud.

Can data be published from a Demilitarized Zone (DMZ)? Yes, DMZ SecureLink can be used as a component of EMS aimed squarely at simplifying the task of securing communications between a DMZ and the cloud environment. To gain some more insight in how secure bridging between IT/OT networks is handled, it is recommended to watch this video: AVEVA Insight and your network.

What if we don’t have all the required data available?

This shouldn’t be a problem, as long as the minimum requirements according to the Data Prerequisites - EMS are met. There should be data for at least 1 energy type (Water, Air, Gas, Electricity or Steam) and 1 type of context (shift, batch, product or material). Next to this, it is also recommended to have a volume measurement in place, to be able to calculate efficiencies. This data should at least be available on Area level (ISA-88). The more energy and context data is available, the more insights EMS should be able to provide.More Insights will likely increase the amount of optimization opportunities.

How easy is it to add new data (tags) to the system?

Adding new data to the system can be done within a few easy steps. In most cases no help from Analytics For Industry or a System Integrator is required. EMS is designed to make its end-users as self-reliant as possible. Once the data is supplied to the system, the metadata should be defined (csv upload or sync setting) according to the system’s standards. When this is done the new data becomes available in the dashboards. For connecting new sites or additional assets it is advised to consult Analytics for Industry.

Belguim HQ

+32 (0)3 328 07 40

Netherlands HQ+31 (0)76 579 41 00

Uilenbaan 90 2160 Wommelgem, België

Minervum 7139 4817 ZN Breda, Nederland